|

|

|

|

|

| Author |

Message |

Hasenbrau

Community Member

Joined: 02 Dec 2008

Posts: 109

Location: SoCal

|

Posted: Thu Oct 28, 2010 10:24 pm Post subject: Hartford Blaster Modifications: Advice? Posted: Thu Oct 28, 2010 10:24 pm Post subject: Hartford Blaster Modifications: Advice? |

|

|

Hey everyone,

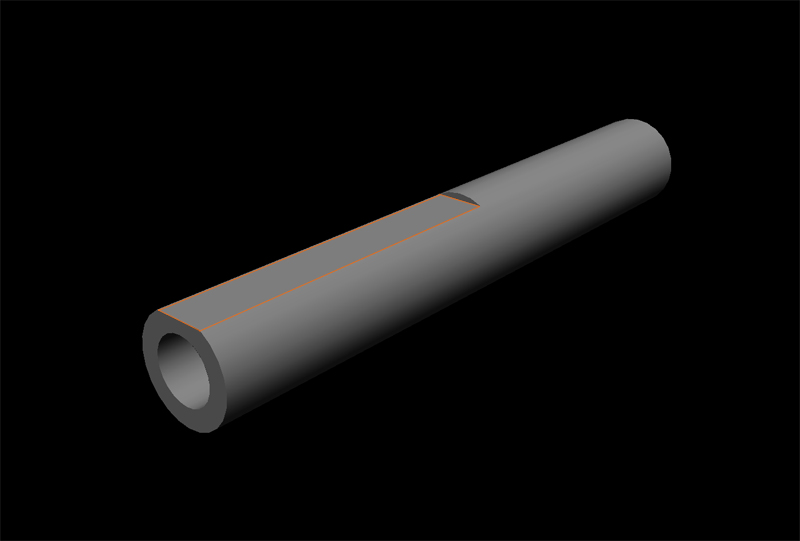

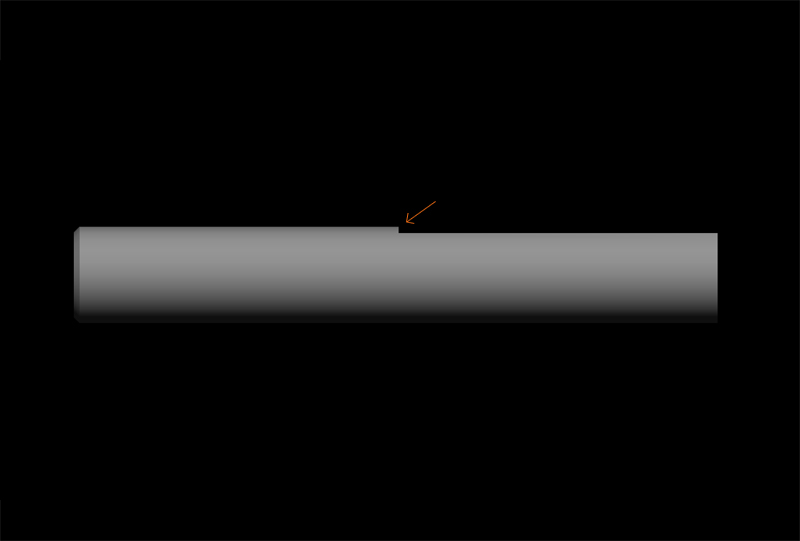

I'm looking for a little advice on a Hartford Blaster modification build I'm working on. One of the changes I'm making is to replace the plastic barrel with one of mspaw's machined barrels I got a while back. The problem I'm having is that the Hartford original barrel has a flat section toward the back, essentially a plain cut into the curve of the barrel about 1/16th of an inch deep. This is used for a thin connecting plate that screws into the top of the bulldog frame and into the top of the barrel. The plates original purpose seems to be a track for the bolt to slide along. I wish to maintain this, but in the case of the metal barrel it is also going to be needed to help support the extra weight up front.

What I'd like to know is how do I go about doing this? I would just take it to a machine shop, but I've been having some bad luck with the local ones. Any suggestions for doing this at home? I've thought about trying to build some sort of jig to mount a grinder sideways and run the barrel along that, but if anyone here's got a better idea I'd love to hear it.

Here's some renderings of what I'm talking about:

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

propsjonnyb

Community Member

Joined: 16 Jul 2009

Posts: 476

Location: Helmdon, Northamptonshire UK

|

Posted: Fri Oct 29, 2010 8:45 am Post subject: Posted: Fri Oct 29, 2010 8:45 am Post subject: |

|

|

| Sidkits, barrels are like this , so you could use a one of those as a replacement . If not fix your barrel in a vice and file it down by hand or use a dremmel tool or an angle grinder. Whatever you use, grind or file it carefully, as it has to be completely flat and straight so the bolt action can move freely and smoothly over the surface. |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

DonParker

Community Member

Joined: 09 Jan 2009

Posts: 250

|

Posted: Fri Oct 29, 2010 9:10 am Post subject: Posted: Fri Oct 29, 2010 9:10 am Post subject: |

|

|

I do that to my barrels for the offworld guns. I then machine

a flat plate and use counter sunk allen screws to fasten it

to the the top of the barrel. I'm sure some other guys that

I've made barrels for can tell you better about what I've done.

Don |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Hasenbrau

Community Member

Joined: 02 Dec 2008

Posts: 109

Location: SoCal

|

Posted: Fri Oct 29, 2010 1:55 pm Post subject: Posted: Fri Oct 29, 2010 1:55 pm Post subject: |

|

|

Thanks for the advice propsjonnyb. I'm not so confident that I could freehand a flat grind like that, though this may end up being the way I go.

Don, I noticed that about your barrels in the pics you've posted. And that is exactly what I want to do. What do you use to make that planer cut? I would just order one of your barrels, but I've already got this steel one, so I'd like to try to use it. If I mess it up you'll be getting a barrel order PM from me

Thanks for the advice guys. |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

DonParker

Community Member

Joined: 09 Jan 2009

Posts: 250

|

Posted: Fri Oct 29, 2010 4:53 pm Post subject: Posted: Fri Oct 29, 2010 4:53 pm Post subject: |

|

|

I have a 1.250 facemill that I use in my mill.

You could probably file it flat . I've seen mspaws

barrels and he did a great job on them although

I never understood what would guide the bolt.

Don |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

propsjonnyb

Community Member

Joined: 16 Jul 2009

Posts: 476

Location: Helmdon, Northamptonshire UK

|

Posted: Fri Oct 29, 2010 5:44 pm Post subject: Posted: Fri Oct 29, 2010 5:44 pm Post subject: |

|

|

| The filing or grinding is relatively straight forward , given you use a set square or T square to maintain the flat smooth surface , you could use a hand file and grit pads to achieve the same effect but it would take some time by hand - I actually prefer hand tooling the pieces as I get a more precise finish , but you gan cat the same effect with power tools, if you take care . |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

|

|

|

|

|

|

|